How to select Core Drilling Equipment for specialized project needs

Comprehending the Relevance of Core Exploration Devices in Modern Construction Projects

Core exploration tools is vital in contemporary building, facilitating accurate openings for different systems. This equipment consists of advanced tools like diamond and carbide-tipped drills, which permit reliable sampling and setup. Spending in high-grade tools not just boosts efficiency yet also boosts safety on-site. Comprehending the complete implications of these tools goes beyond simple capability. The ins and outs of their applications and future fads require more exploration.

Sorts Of Core Exploration Tools

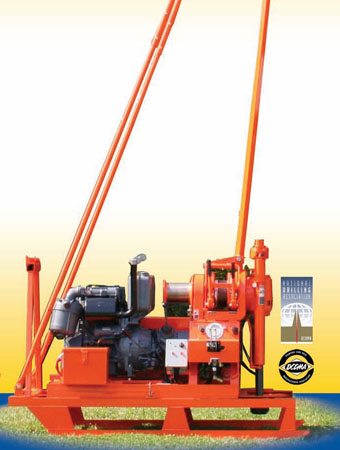

When exploring the numerous types of core exploration devices, it ends up being evident that each tool is created for particular applications and products. Core drills come in numerous kinds, consisting of diamond core drills, which are excellent for hard materials like concrete and rock because of their precision and sturdiness. One more type is the carbide-tipped core drill, suited for softer substrates such as asphalt and block. Furthermore, the rotating drill is frequently used for basic objectives, giving versatility throughout various projects.

Mobile core exploration equipments, preferred for their movement, allow for on-site procedures in confined rooms. Alternatively, bigger, stationary rigs are utilized for extensive exploration jobs, commonly in industrial settings. Each item of tools is complemented by numerous drill bits, tailored to the solidity and structure of the material being passed through - Core Drilling Equipment. Understanding these differences is crucial for selecting the proper tools for reliable core drilling in building and construction projects

Applications of Core Drilling in Building And Construction

Core drilling plays a crucial duty in various construction applications, as it permits efficient and specific material removal in a variety of jobs. Among the primary applications is in the setup of pipes and electric systems, where exact holes are required for pipes and conduits to travel through wall surfaces and floorings. In addition, core drilling is made use of for sampling purposes, making it possible for designers to extract round samples of concrete or dirt for screening and evaluation.

Another significant use core exploration remains in the creation of anchor factors, which are essential for protecting structural aspects such as beams and columns. It is additionally used in renovating existing structures, permitting alterations without compromising the stability of surrounding materials. Core drilling helps with the installation of Cooling and heating systems by giving openings for ductwork. Generally, these applications demonstrate core drilling's critical payment to contemporary building and construction efficiency and accuracy.

Advantages of Purchasing Top Quality Devices

Purchasing high quality tools is important for ensuring excellent efficiency and longevity in building projects. Top notch core drilling tools uses superior precision, enabling service providers to accomplish accurate results while decreasing material waste. These tools are designed to withstand extensive usage, leading to reduced maintenance expenses and longer life-spans. Reliable devices can greatly enhance efficiency, enabling teams to complete tasks more effectively and satisfy job target dates.

One more benefit is that quality devices commonly feature enhanced safety functions, offering drivers with far better control and lowering the risk of crashes. In addition, investing in reliable brands can lead to much better customer support and warranty services, guaranteeing that any type of issues can be settled swiftly. Eventually, the ahead of time financial investment in quality devices settles in the lengthy run, causing raised general job efficiency, minimized downtime, and greater client fulfillment via premium craftsmanship.

Safety And Security Factors To Consider When Utilizing Core Exploration Devices

Ensuring safety and security while utilizing core drilling tools is extremely important to avoid mishaps and injuries on building and construction websites. Operators has to put on ideal personal protective tools (PPE), including helmets, handwear covers, and eye defense, to minimize dangers connected with flying debris and equipment breakdowns. Proper training is crucial, as it furnishes workers with the expertise to manage equipment securely, acknowledge potential dangers, and perform emergency treatments.

Routine maintenance and examination of core drilling tools can aid determine deterioration, decreasing the chance of tools failure throughout operation. Furthermore, keeping a organized and tidy workplace reduces tripping risks and guarantees that employees can operate equipment safely. Communication among staff member is critical, as it fosters a society of safety and security where everybody knows their environments and potential dangers. By focusing on these safety considerations, building projects can run much more successfully while securing the these details well-being of all employees included.

Future Trends in Core Boring Modern Technology

Innovations in core boring innovation are poised to reinvent the building and construction sector, structure on the safety and security actions currently highlighted in existing practices. Emerging fads include the combination of robotics and automation, which aim to boost accuracy and performance while minimizing human error. In addition, the growth of lightweight, mobile equipment is making core boring a lot more accessible, enabling for less complicated transportation and arrangement on diverse job sites.

Developments in diamond drill little bit modern technology are resulting in longer-lasting tools that can cut via different products with decreased downtime. The incorporation of information analytics and IoT technology is likewise anticipated to improve surveillance and maintenance, ensuring suitable efficiency and lessening operational costs. On top of that, sustainable practices are gaining traction, with manufacturers concentrating on eco-friendly products and energy-efficient equipment. Collectively, these trends content represent a transformative change, assuring to improve productivity while focusing on safety and ecological obligation in core exploration operations.

Often Asked Inquiries

Just how Do I Choose the Right Core Exploration Devices for My Task?

To select the best core exploration equipment, one need to evaluate task requirements, figure out the product type, review the called for hole size, and think about the tools's source of power and portability to guarantee peak efficiency and effectiveness.

What Is the Average Life-span of Core Boring Devices?

The typical lifespan of core drilling tools usually varies from five to 10 years, depending upon use intensity, upkeep methods, and material types. Proper care can greatly extend their operational longevity, improving general performance.

Can Core Boring Equipment Be Rented As Opposed To Acquired?

Yes, core exploration equipment can be leased rather of acquired. Many building business go with leasings to lower costs and stay clear of maintenance obligations, particularly for temporary tasks where acquiring would certainly be impractical or unneeded.

What Upkeep Is Needed for Core Drilling Machines?

How Does Core Exploration Effect Surrounding Structures Throughout a Project?

Core exploration can affect surrounding structures by creating vibrations and small shifts in structure security. Appropriate strategies and devices are vital to decrease these results, making sure security and integrity of surrounding buildings throughout construction activities.

Core exploration devices is essential in modern construction, helping with accurate openings for numerous systems. When look at this site exploring the different kinds of core drilling tools, it becomes noticeable that each tool is created for details applications and materials. Core drills come in a number of types, including ruby core drills, which are excellent for tough materials like concrete and rock due to their precision and resilience. Assuring safety and security while making use of core boring tools is extremely important to stopping mishaps and injuries on building and construction websites - Core Drilling Equipment. Regular upkeep and evaluation of core boring devices can help determine wear and tear, minimizing the chance of tools failure during procedure